Making the cough drops

A craft full of passion

Making the herbal drops

Making herbal drops is an ancient craft full of tradition that requires great sensitivity, energy and skill in handling ingredients, heat and the right kneading of the herbal drop mixture. In the next few sections, we invite you to join us on a journey to see how small green herbal drops with a flag are created from the individual ingredients.

1. Step - mixing and dissolving

The ingredients sugar and water are measured out and mixed together. When the sugar has dissolved, glucose syrup or flavour-giving ingredients such as honey or malt are added.

2. Step - cooking

The ingredients are cooked at a temperature of 140°C to 150°C. When this has been done and the water solution has been removed, the herbal extracts can be added.

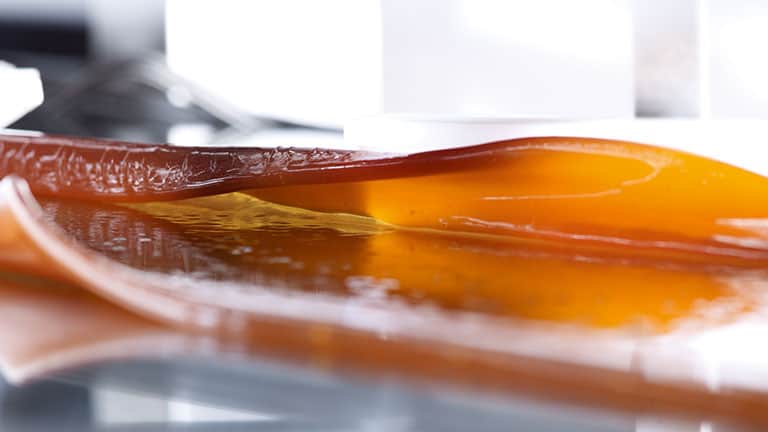

3. Step - mixing and kneading

Acids, natural colours and natural flavourings and oils are now added. The added ingredients are distributed evenly by kneading. At the same time, air is pressed out of the mass until the mass reaches approx. 86°C.

4. Step - forming

The cough drop mass is now ready for the forming line. Here, the mass is first formed into an increasingly tapered strand to be extruded through the die forming machine.

5. Step - cooling and wrapping

The last step is to cool down the still warm herbal drops to about 20°C and then wrap them in our characteristic flag and our green cough drop wrapper and put them in the bag.

Making herbal drops is an art

The nose of a perfumer and the palate of a sommelier – and just the right movement

It depends on the stirring action. And the temperature. And the quality of the ingredients. And the recipe. Get the details right and the herbal drop will be a pleasure to eat and its flavour will be an experience to be savoured. Making premium herbal drops is an art. Herbal drops have zero tolerance. One mistake in the production process and it will stick to the wrapper in the bag. Another mistake and the aromas will be lost. Real herbal drop confectioners are initiated into the secrets of their craft. They can sense what the herbal drop lover wants and know every step of the production process. And this begins with the selection of the ingredients.

Selected with care

The quality of all the ingredients is key, primarily the quality of the essential oils, fruit juices and herbal extracts. We know our suppliers, check that their cultivation methods are to our satisfaction and take care not to buy mass-produced articles. Some of them are based locally in our Franconian homeland. Our herbal drop confectioners have the nose of a perfumer and can detect the minutest differences and the finest nuances. We only allow top quality into our pans even though these are obviously on the large side.

Gentle production methods

Having carefully selected the ingredients, added the sugar or sugar substitutes, the glucose syrup, citric acid or malic acid, the next challenge is making them using a gentle processing technique. The herbal drop mass requires a precise temperature, especially because of the sugar. And just the right stirring action too.

Our herbal drop confectioners are so practised at stirring the valuable ingredients, they could do it standing on their heads. They know the production process, all the idiosyncrasies of the herbal drop mass and know how to make it really smooth. They are the extended arm of our machines. They set the pace and the machine obeys. If something is not quite right, they take immediate action. Even if there is a machine breakdown. Because our herbal drop confectioners are mechanics, too. They make sure things run smoothly in production where conditions comply with the latest standards.

Sound training

"Confectionery" – there is a solid profession behind this simple-sounding word: confectionery technology. This involves three years of training with a block of 12 weeks each year at the Zentralfachschule der Deutschen Süßwarenwirtschaft (ZDS) in Solingen, the only vocational training school for sugar confectioners in Germany. Subjects on the timetable include production engineering, technology, mathematics, chemistry, biology, physics and nutritional science. Then, of course, there are subjects like confectionery, long-life bakery products, chocolate and sweets. Not everyone is cut out for the art of making confectionery.

Even we don't always manage to find the right apprentice every year, unfortunately. There are currently ten confectioners working with us, many of whom come top of their year group. That makes us proud. A passion for confectionery and cooking are important prerequisites. Also an instinctive feel for the ingredients, respect for foodstuffs and a stable character. A keen nose and a fine palate are also indispensable. After all, confectioners turn into sommeliers, relishing the rich and full-bodied flavour of their specialities on the tongue.

Why? Because only premium herbal drops which meet our standards and conform to the original recipe make it into the bag. This is why you can always rely on the quality and flavour of our Em‑eukal herbal drops.